Click here to download a copy of our company profile.

Berry Place offers a wide range of creative services. Through a combination of photo-realistic rendering, 2D and 3D computer aided modelling and materials development, we add form, colour and structure to bring original ideas to life.

Our highly motivated and skilled team have been providing 3D solutions to all areas of the creative industry for more than twenty years. The diverse range of clients we serve includes product and packaging designers, advertising agencies, manufacturers, exhibition designers, photographers and entrepreneurs.

Conveniently situated just a short walk from Cambridge Heath Overground Station, we can offer our clients ample access to review projects during the course of their development. What sets us apart, above and beyond our commitment to quality, is our ability to balance innovative technical processes with genuine creativity and overall problem-solving expertise.

This combination ensures that we consistently deliver exceptional solutions, on time and at a competitive price. Our variety of specialist skills and understanding of production and manufacturing constraints means that we are able to quickly bring ideas to reality, enabling our clients to make informed decisions for the development, testing and marketing of their products.

Our ability to meet the extraordinary range of enquiries from our clients requires a broad knowledge of manufacturing techniques and a skilled and versatile team to realise ideas.

Our ability to meet the extraordinary range of enquiries from our clients requires a broad knowledge of manufacturing techniques and a skilled and versatile team to realise ideas.

Whether it's an individual commission or a low-volume production run, we are often involved at the design stage, liaising between clients and manufacturers to define the design and transform the concept into the finished product.

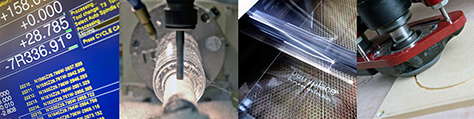

Our in-house services include CAD data creation, 3 and 4 axis CNC machining, laser cutting and engraving, CNC routing, vacuum forming, moulding and vacuum casting combined with handcrafting skills and spray finishing.

Our in-house services include CAD data creation, 3 and 4 axis CNC machining, laser cutting and engraving, CNC routing, vacuum forming, moulding and vacuum casting combined with handcrafting skills and spray finishing.

For projects requiring more specialised processes, we have developed a trusted network of individual craftsmen and suppliers. From the rapid prototyping of SLA or SLS components, anodising, electro-forming and water jet cutting, to fluorescent flocking and leather embossing, we have a supplier on hand.

This unique access to information, materials and services - both nationally and internationally - combined with our ability to work to exacting timescales, enables us to deliver complete, confidential and competitive solutions of the highest quality.

This unique access to information, materials and services - both nationally and internationally - combined with our ability to work to exacting timescales, enables us to deliver complete, confidential and competitive solutions of the highest quality.